APFC - Automatic Power Factor Controller Panels

APFC panels or the APFC full form - Automatic Power Factor Controller Panels are mainly used for the improvement of Power Factor.

The Power Factor is that ratio of active power to apparent power and it is a most important component in measuring electrical consumption. APFC is an automatic power factor control panel which installed to improve poor power factor, whenever required, by switching ON and OFF capacitor bank units as per requirement automatically. APFC Panels are mainly used for sustainment of Power Factor as per State Electricity Board.

Why are APFC Panels required?

In industries, most of a part of the load is inductive in nature and requires reactive power for current magnetization. This reactive power is mostly waste and not utilized for any actual work. And this results in a requirement for extra power to run a machine from the actual needs. This leads to a low power factor and may cause voltage fluctuations, power issues, operational losses, also as higher electricity bills and heavy penalties.

Everyone knows that now-a-days how costly electricity is computed. Thus it becomes most important to lower electrical consumption for reducing expenditure and economizing operation at desired power factor to avoid unwanted electricity penalty rising due to continuous power factor drop.

Benefits of using APFC panels

- APFC Panels help you reduce the Penalties from the Electricity Board.

- APFC panels help to reduce Reactive Power and Apparent Power Demand.

- APFC panels also help to avoid PF Surcharges & max Demand Penalties.

- It reduces the risk of Operational Issues and loss of power.

- APFC panels provide consistent PF Correction even under fluctuating power loads.

- The Automatic Control System effectively switches the capacitor ON or OFF whenever you require.

- It continuously monitors the load and takes action based on the microprocessor relays.

- It has a User-Friendly Interface.

- It helps you to reduce electricity consumption and reduce your bills.

- APFC panels likewise minimize Harmonic Disruption too.

- APFC panels are durable and resistant to corrosion.

- APFC Panels also protect electrical equipment from damage.

Automatic Power Factor Correction - How it's done?

APFC Panel with stage based pre-programmable micro-controller of various make which triggers the capacitor banks of suitable capacity automatically in multiple stages by directly sensing the reactive load which works on principle of VAR (Volt Ampere Reactive) sensing tends maintain the PF to 0.99 Lag. The capacitor banks are selected in number of stages as 4/6/8/12/16 consistent with the load pattern of the customer.

APFC Panels serves the purpose to achieve Power Factor to 0.99 Lag. For this purpose, operation of these control panels becomes most essential in those industries where electrical installations are supposed to cater to large electrical load.

Principle of reactive energy management

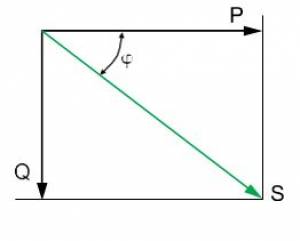

All Alternating Current electrical networks consume two sorts of power: Active power (kW) and Reactive power (kVAR):

- The active power P (kW) is real power transmitted to loads like motors, lamps, heaters, computers .The electrical active power is transformed into mechanical power, heat or light.

- The reactive power Q (kVAR) is utilized only to supply the magnetic circuits of machines, motors and transformers.

- The apparent power S (kVA) is the vector combination of active and reactive power.

In this diagrammatic representation, Power Factor (P/S) is equal to cosφ.

The circulation of reactive power within the electrical network has major technical and economic consequences. For an equivalent active power P, higher reactive power means a higher apparent power and thus, a higher current must be supplied.

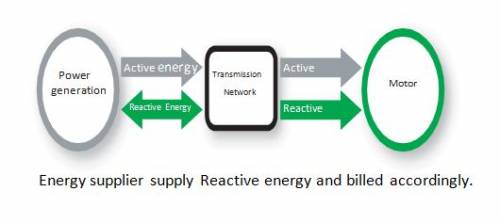

- The circulation of active power over time is leads to active Energy (in kWh).

- The circulation of reactive power over time is leads to reactive Energy (kVARh).

- In-circuit, the reactive energy is supplied additionally to the active energy.

Because of this higher supplied current, circulation of reactive energy on distribution networks results in:

- Overload of transformers,

- High temperature rise of supply cables,

- Additional losses,

- Large voltage drops,

- Higher energy consumption and cost,

- Less distributed active power.

For all these reasons, there's an excellent advantage to generate reactive energy at the load level so as to stop the unnecessary circulation of current within the network. This is what's referred to as “Power Factor Correction”.

This correction is obtained by the connection of capacitors, which produce reactive energy in opposition to the energy absorbed by loads like motors.

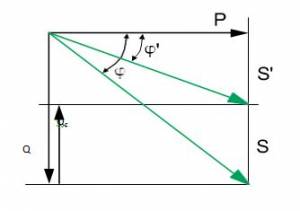

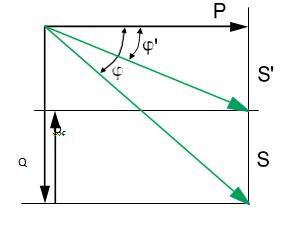

The result is a reduced apparent power, and an improved power factor P/S’ as described in the diagram.

The power generation and transmission are partially relieved, thus reducing power losses and making additional transmission capability available. Capacitors supply the reactive power. Therefore, no billing of reactive power by the energy supplier.

Calculation of required capacitor:

The aim is to determine the requested reactive power QC (kvar) to be installed, so as to improve the power factor cosφ and reduce the apparent power S.

For φ’ < φ, we’ll get: cosφ’ > cosφ and tanφ’ < tanφ. This is shown in the diagram.

QC can be determined from the formula:

QC = P X (tanφ - tanφ‘), which is deduced from the diagram.

QC: power of the capacitor bank, in kVAR

P: active power, in kW

tanφ: (tangent of the phase angle - before compensation)

tanφ‘: (tangent of the phase angle - after compensation)

The parameters φ and tan φ are obtained from the billing data, or from direct measurement in the installation.

Please Contact Us if you want us to provide a quote to you for APFC Panels and do the calculations for you.

Applications where we can use these panels are:

- Automobile Industries.

- Metal Industries.

- Pharmaceutical Industries.

- Cement Industries.

- Chemical Plants.

- Windmills & Power Stations.

- Textile Machinery.

- Printing Industries.

- Railways.

- Hospitals, Malls, Banks, and IT Parks.

- Commercial Complexes.

- Food Processing Plants.

Specifications:

Voltage: 440/415 V AC

Phase: 3 Phase

Frequency: 50 Hz

Capacity: Upto 60 kVAR

Country of Origin: Made in INDIA

PFR: 4 / 8 / 12 / 16 / 20 / 24 - stage control

IoT Enabled APFC Panel